Вы когда-нибудь задумывались, почему некоторые материалы служат десятилетиями, в то время как другие быстро выходят из строя? Что если я скажу вам, что секрет заключается в специальном покрытии, которое может значительно продлить жизнь вашего оборудования? Износостойкие покрытия – это не просто модное слово, а реальное решение для множества промышленных и бытовых проблем. В этой статье мы подробно разберем, что такое износостойкие покрытия, как они работают, и почему они так важны для обеспечения долговечности.

Но прежде чем углубляться в детали, давайте зададимся вопросом: как часто вы сталкиваетесь с износом в повседневной жизни? Возможно, это стирание подошвы обуви, царапины на автомобиле или коррозия металлических деталей. Все эти проблемы могут быть решены с помощью правильного покрытия. Износостойкие покрытия предназначены для защиты поверхностей от механического, химического и термического воздействия, что делает их незаменимыми в современных технологиях.

Что же делает износостойкое покрытие таким эффективным? Оно обычно состоит из прочных материалов, таких как керамика, карбиды или полимеры, которые наносятся тонким слоем на базовый материал. Этот слой действует как барьер, поглощая удары, трение и другие формы износа. Например, в автомобильной промышленности такие покрытия используются для защиты двигателей и трансмиссий, значительно увеличивая их срок службы. Но как именно это работает? Давайте explore this further.

Один из ключевых аспектов – адгезия, или способность покрытия прочно связываться с поверхностью. Если покрытие плохо адгезирует, оно может отслоиться под нагрузкой, что приведет к failure. Поэтому современные технологии включают предварительную обработку поверхностей, such as sandblasting or chemical etching, to ensure a strong bond. Additionally, the composition of the coating is tailored to specific applications. For instance, in high-temperature environments, coatings with ceramic components are preferred due to their thermal stability.

Another important factor is the thickness of the coating. Too thin, and it might not provide adequate protection; too thick, and it could crack or peel under stress. Engineers carefully calculate the optimal thickness based on the expected wear conditions. This is why customization is crucial – a one-size-fits-all approach doesn't work here. But how do you know which coating is right for your needs? That's where testing and expertise come into play.

Laboratory tests, such as abrasion resistance tests and hardness measurements, help determine the performance of different coatings. For example, the Taber Abrasion Test is commonly used to simulate wear over time. By analyzing the results, manufacturers can recommend the best coating for a particular application. But it's not just about laboratory data; field experience also plays a vital role. Many companies have case studies showing how wear-resistant coatings have saved them millions in maintenance costs.

Let's take a real-world example: in the mining industry, equipment is subjected to extreme abrasive wear from rocks and minerals. Without proper protection, components like crusher jaws and conveyor belts would need frequent replacement, leading to downtime and high expenses. By applying wear-resistant coatings, companies can extend the life of these parts by up to 300%, resulting in significant cost savings and improved efficiency. But is it only for heavy industry? Absolutely not!

In consumer products, wear-resistant coatings are used in things like smartphones and watches to prevent scratches. Have you ever wondered how your phone screen remains relatively scratch-free despite daily use? It's often due to a hard coating like sapphire crystal or reinforced glass. Similarly, in the aerospace industry, coatings protect turbine blades from high-temperature corrosion, ensuring safe and reliable flight. The applications are virtually endless, from medical devices to construction materials.

But what about the environmental impact? Some might worry that these coatings involve harmful chemicals or processes. However, many modern coatings are designed to be eco-friendly, using water-based formulas or recyclable materials. Moreover, by extending the life of products, they reduce waste and the need for frequent manufacturing, which overall benefits the environment. So, not only do they protect surfaces, but they also contribute to sustainability.

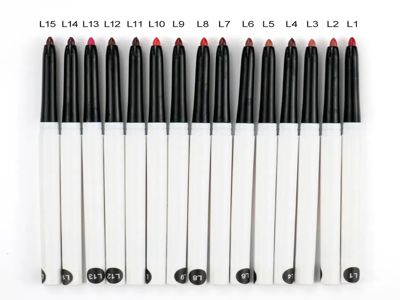

Now, let's delve into the types of wear-resistant coatings. There are several categories, including thermal spray coatings, PVD (Physical Vapor Deposition), CVD (Chemical Vapor Deposition), and powder coatings. Each has its advantages and is suited for different scenarios. Thermal spray, for example, involves melting a material and spraying it onto a surface, making it ideal for large components. PVD and CVD are more precise, often used for thin films in electronics. Powder coatings are common for aesthetic and protective purposes on metals.

The choice of coating depends on factors like the base material, the type of wear (abrasive, adhesive, corrosive), and the operating conditions. For instance, if you're dealing with constant friction, a coating with high hardness like tungsten carbide might be best. For chemical resistance, polymers or ceramics with inert properties are preferred. It's a complex decision that requires expert consultation, but the benefits are clear: reduced maintenance, longer lifespan, and overall cost efficiency.

How do these coatings actually enhance durability? By providing a sacrificial layer that takes the brunt of the wear, the underlying material remains intact. This is similar to how a knight's armor protects them in battle – the armor gets damaged, but the person is safe. Over time, as the coating wears down, it can often be reapplied or repaired, further extending the life of the product. This makes it a cost-effective solution in the long run.

But what about the initial cost? Some might hesitate due to the upfront investment. However, when you consider the total cost of ownership – including replacement parts, downtime, and labor – wear-resistant coatings often pay for themselves quickly. For businesses, this means higher profitability and reliability. For consumers, it means products that last longer and perform better, reducing the frustration of frequent replacements.

In conclusion, wear-resistant coatings are a powerful tool for achieving durability and protection across various industries. They work by forming a robust barrier against wear, tailored to specific needs through advanced materials and application techniques. Whether it's in heavy machinery, everyday gadgets, or critical infrastructure, these coatings help ensure that things last longer and perform better. So next time you see something that seems indestructible, remember – there's probably a clever coating behind it!

This article has only scratched the surface of this fascinating topic. If you're interested in learning more or implementing wear-resistant coatings in your projects, consult with experts who can provide personalized advice. After all, in a world where efficiency and sustainability are key, investing in durability is always a smart move.